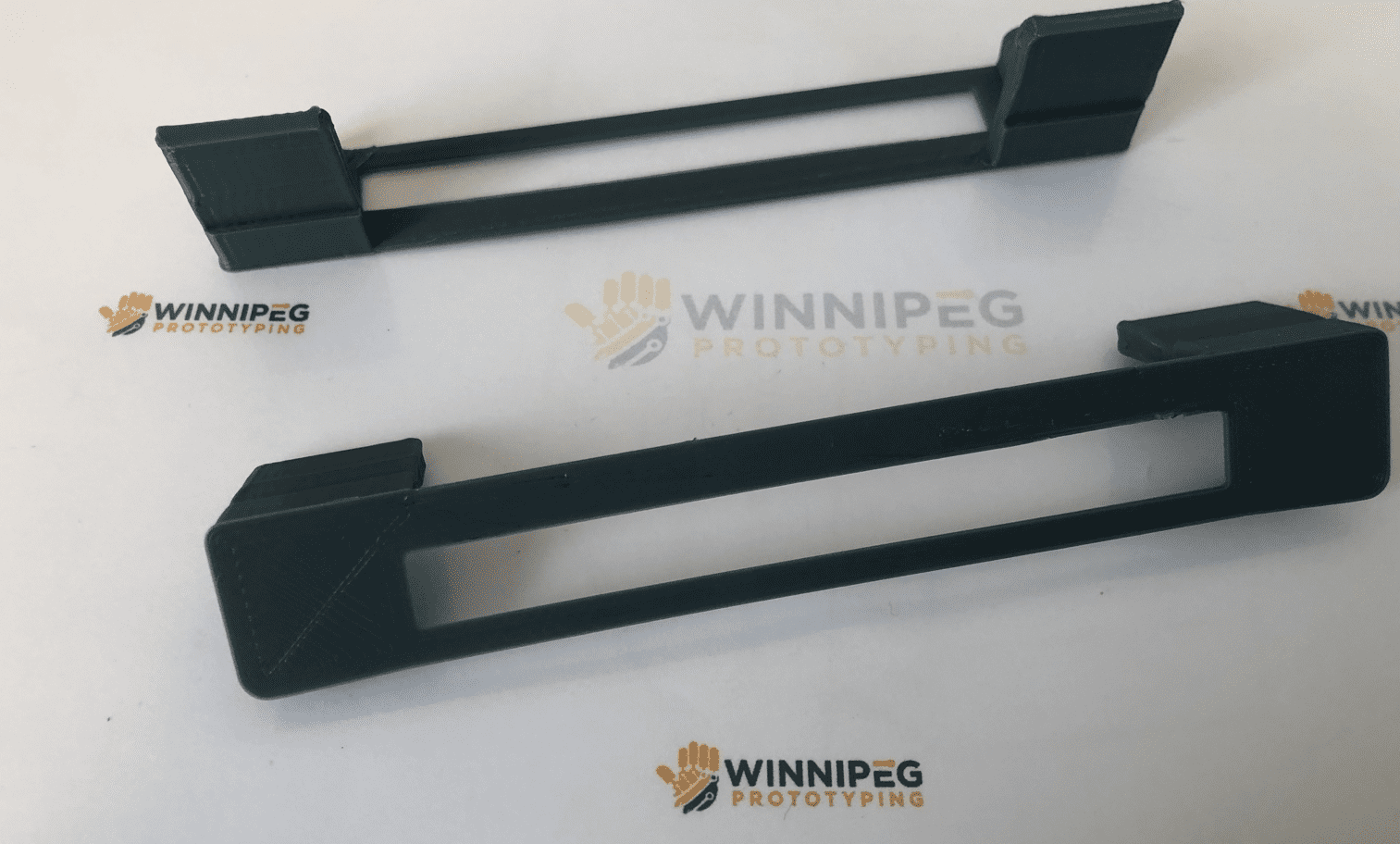

FDM and Resin 3D Printing according to your needs with high-quality materials.

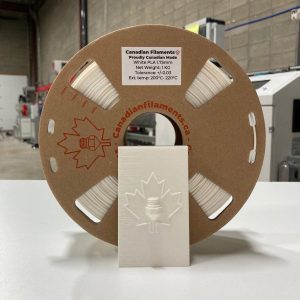

We have Black and White colors in stock at any time. If you are interested in a different color we will order it free of charge and have the print ready as soon as possible.

With available materials, we can deliver the FDM 3D printed parts in the next day (depending on the length of print).

Shipping time 2-5 days(depending on the shipping method you select and where you live in Canada)

Pickup is available in the Winnipeg city area.

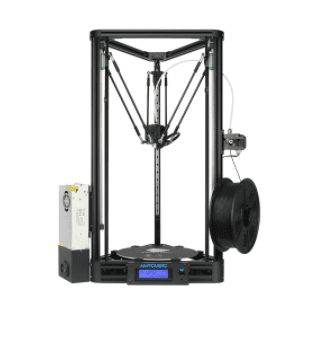

Fused Deposition Modeling (FDM) 3D printer

Fused Deposition Modeling (FDM): FDM is one of the most widely used and accessible 3D printing methods. It works by extruding melted thermoplastic filament through a heated nozzle onto a build platform layer by layer. The nozzle moves in the X and Y axes, while the build platform moves in the Z-axis to create the 3D object. Some key points about FDM 3D printing include:

-

- Materials: FDM printers can use various materials, primarily thermoplastics. Such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and more. These materials come in the form of filaments.

- Strength and Durability: FDM-printed parts tend to be relatively strong and durable, especially when using high-quality filaments. The layer adhesion may result in visible layer lines on the surface.

- Applications: FDM is commonly used for rapid prototyping, functional parts, hobbyist projects, educational purposes, and custom household items.

- Post-Processing: FDM-printed objects may require some post-processing, such as removing support structures, sanding, and painting, to achieve a smoother and more refined appearance.

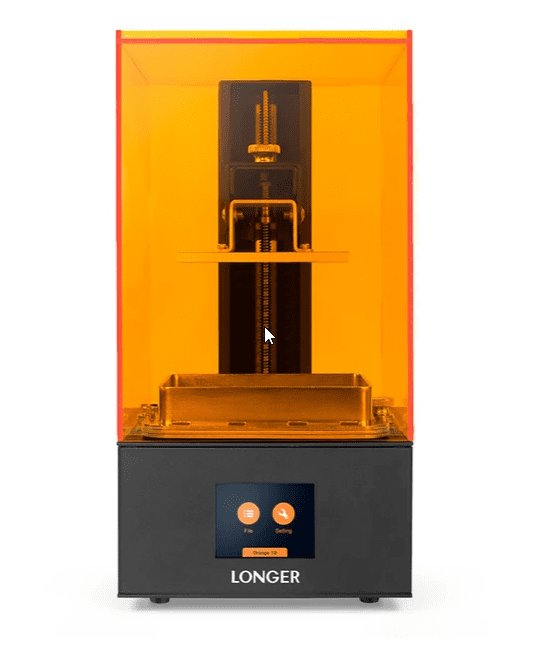

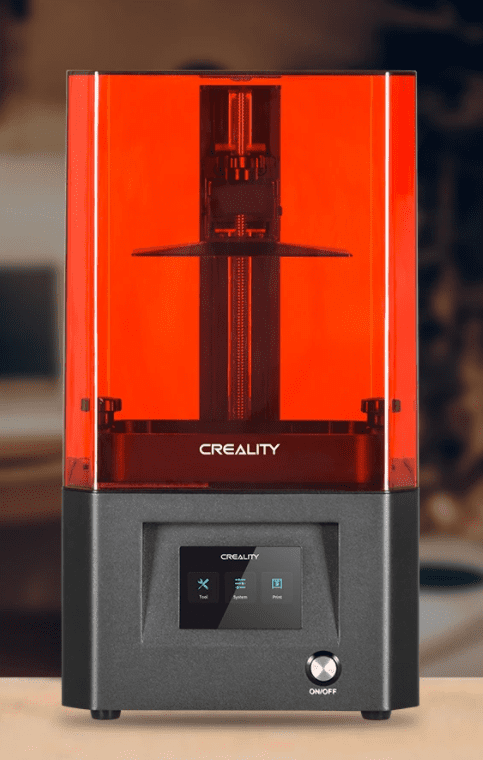

Fused Deposition Modeling Resin 3D printer

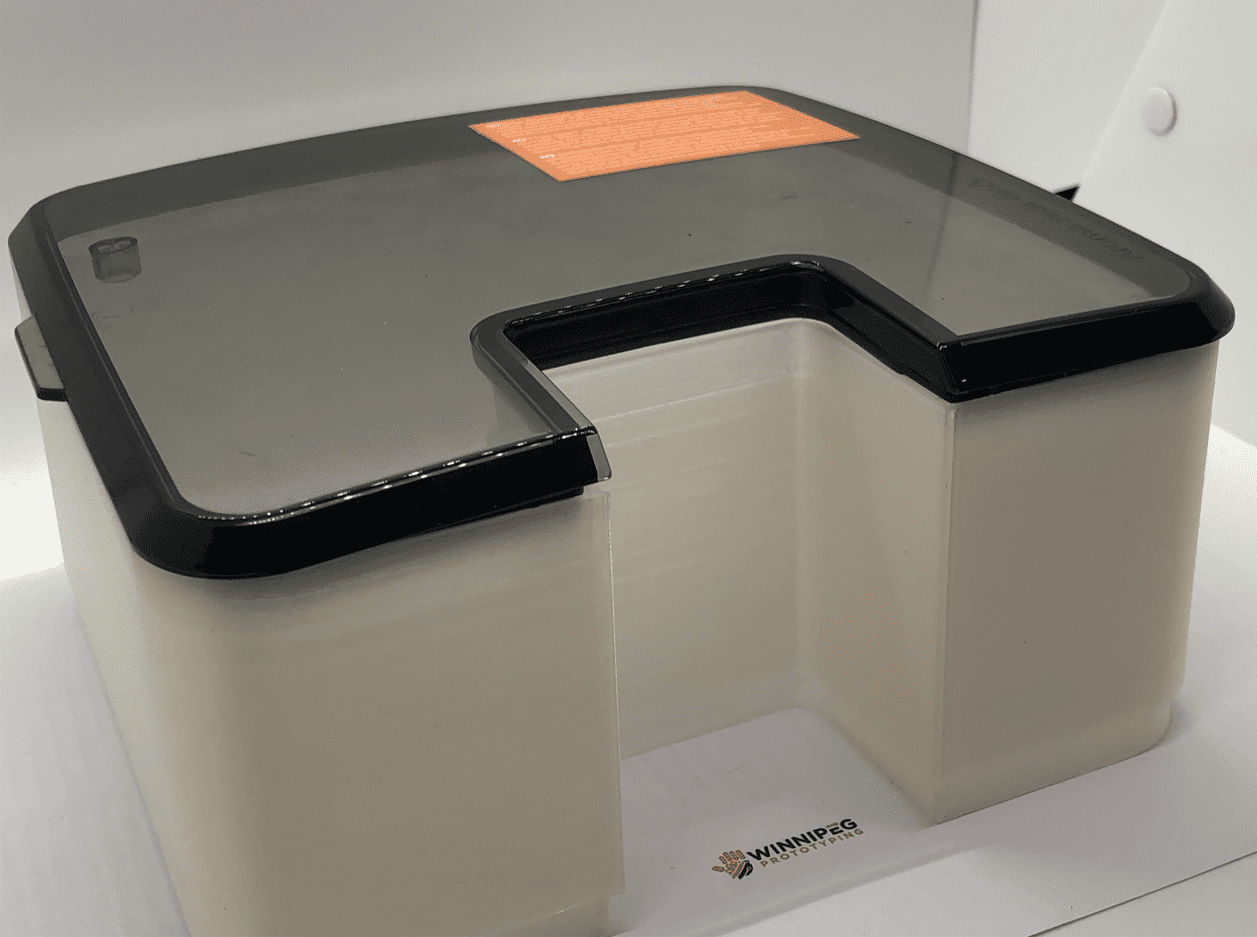

Resin 3D Printing: Resin 3D printing, also known as Stereolithography (SLA) or Digital Light Processing (DLP). Uses a liquid photopolymer resin that hardens when exposed to specific wavelengths of light. A light source (usually a UV laser or a UV projector) selectively cures the resin layer by layer, creating the final 3D object. Key points about Resin 3D printing include:

-

- Materials: Resin 3D printing uses various types of photopolymer resins, including standard resins for general purposes. As well as specialty resins for specific applications like flexible, high-temperature resistant, or castable resins.

- Detail and Surface Finish: Resin 3D printers can produce highly detailed and smooth objects, often with intricate features and fine details. The surface finish is generally superior to FDM printing, making it ideal for aesthetic and high-quality models.

- Applications: Resin 3D printing is commonly used in jewelry making, dental and medical models, miniatures, artistic creations, and other applications that require high detail and accuracy.

- Post-Processing: Resin prints require post-curing after printing to fully solidify the resin. Additionally, they may need to be washed in isopropyl alcohol to remove excess uncured resin. Some post-curing setups include UV chambers or dedicated curing stations.

Related Categories: 3d Printing | Filaments

– Theo Coutu

Very helpful, excellent service.

– Yvan Bruneau

Great service, will be using them again for other projects in the future

– Jared

Great team to deal with. I’m a complete noob when it comes to 3d printing so I didn’t know what to expect. Requesting a quote online was straight forward. I used plans I found online from thingiverse. I used local pickup and my orders were ready as expected. If I ever need something in the future I was use them again.

– Huy Hoang Bui

Amazing final product! Reasonable price as well. I received some helpful advice before deciding my final design as well!

– Huy

Amazing final product! Reasonable price as well. I received some helpful advice before deciding my final design as well!

– Huy

Got great advices while choosing material for my 3d printing. Reasonable price as well. Pretty happy with my final product