Design Anywhere, Print Everywhere – Your Ideas Realized, Without the Shipping Woes!

Unlock the possibilities of remote 3D printing with Winnipeg Prototyping. Let’s collaborate from a distance, creating, refining, and transforming your concepts into exceptional prototypes.

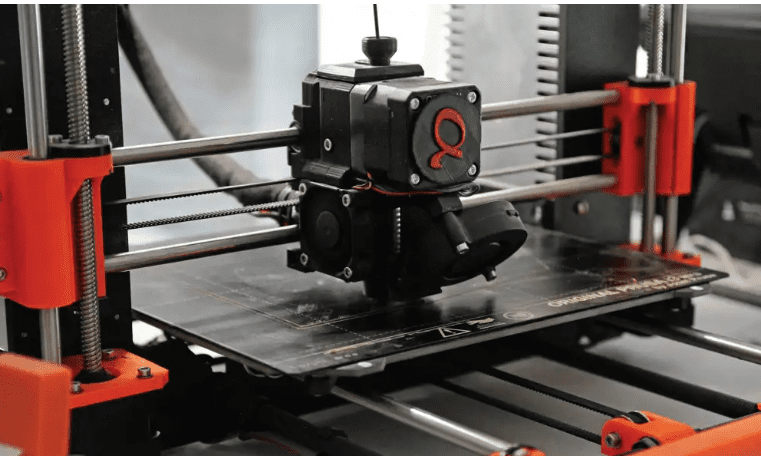

Are you seeking a convenient, cost-effective solution to bring your 3D printing designs to life without the hassles of shipping? Winnipeg Prototyping brings forth a cutting-edge remote 3D printing service designed to streamline your prototyping journey.

Efficiency in Collaboration

Our remote 3D printing service operates on a simple principle: You Design – We Print – Check – Iterate. You design your prototypes from the comfort of your workspace while we handle the printing, ensuring precise execution of your specifications.

Reduced Shipping Costs

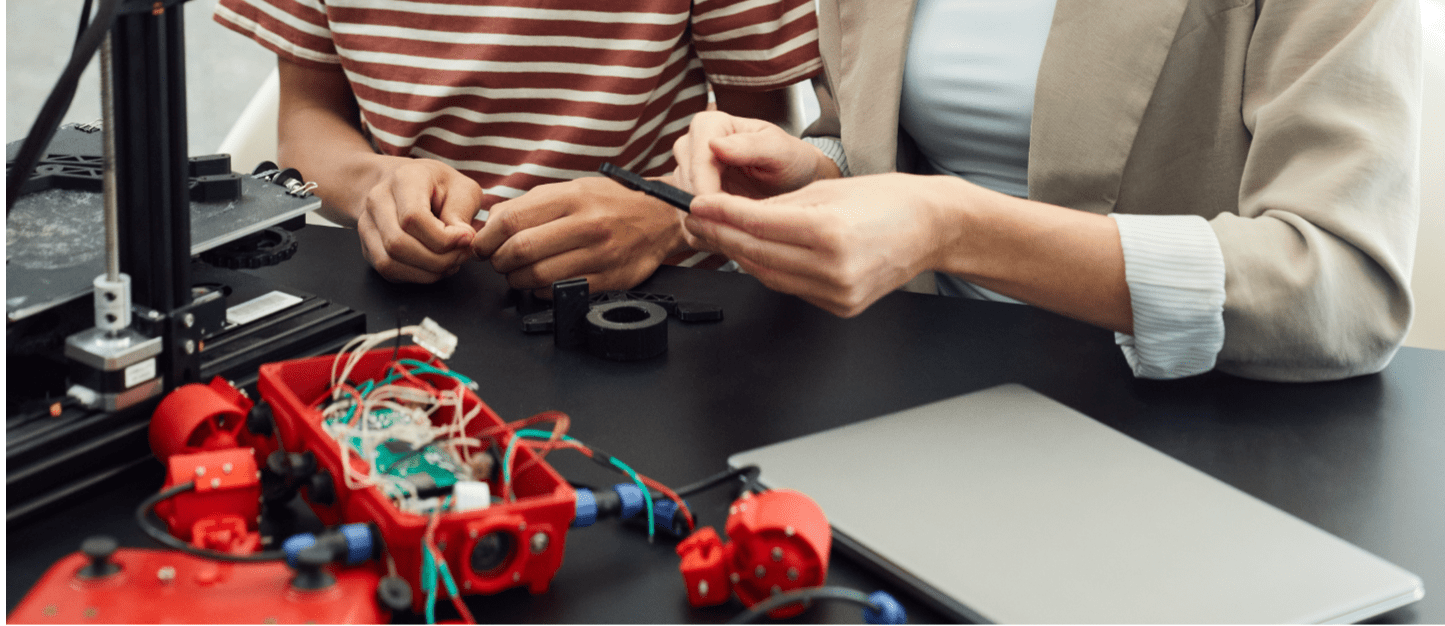

Say goodbye to the headaches of shipping expenses and delays. With remote 3D printing, distance becomes irrelevant. You can securely transmit your designs to our expert team, who will swiftly and accurately materialize them into tangible prototypes. No need for shipping back and forth, which ultimately saves you time and money.

Faster Iteration and Feedback Loops

By leveraging our remote 3D printing services, you’ll experience faster iteration cycles. Once printed, we’ll promptly verify the results, allowing for quick adjustments or improvements. This iterative process significantly expedites the development phase, ensuring your prototypes are perfected swiftly.